Product categories:

Compressed Air generation

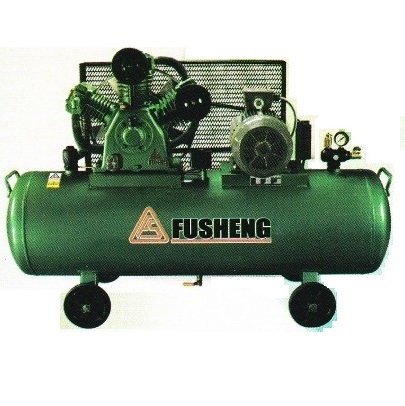

Elevate Your Compressed Air Generation With Precision.

Compressed Air Treatment:

Keep Your Air Dry for Efficient Operation

Filtration & Purification:

Ensure Pure and Clean Compressed Air

Compressed Air Storage:

Explore our local air receivers, proudly made in Malaysia and JKKP approved. Sizes range from 30L-2000L.

Process Condensate Drains:

Efficiently manage your process condensate with our drain solutions.

Consumables:

Ensure the longevity of your equipment with our high-quality aftermarket service kits, designed to keep your compressors running smoothly.

Components and Accessories:

Discover the accessories and components you need to fine-tune and maintain your air compressor system for peak performance.

SP Air Tools & Accessories:

Top-quality air tools with exceptional torque, durability, and precision, SP Air Tools deliver the performance you demand. Elevate your industrial tasks with tools designed for excellence.

Air Compressor Oil

A premium air compressor oil ensures optimal performance and longevity. Specially formulated for industrial applications, it provides superior lubrication, reducing wear and enhancing efficiency. Trust RC8 for reliability in every compression cycle."